Pre-stressed wires and strands reinforce prefab constructions and precast elements. Their consistent mechanical properties, excellent corrosion resistance and low relaxation provide even compressive force to the concrete.

We offer a wide range of high tensile wires and strands. Our line of high quality wires includes different diameters and surfaces (smooth, indented and galvanised).

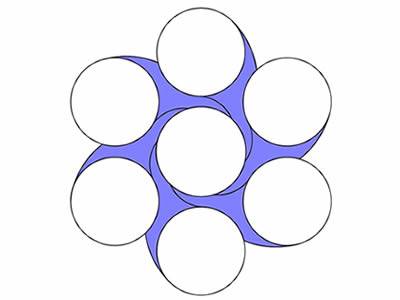

Although various types and diameters are available the most popular in the UK is the 7 wire strand with a 1860 N/mm2 tensile strength in the following diameters: 9.3mm, 12.5mm & 15.7mm.

The standard full load is 25 tonnes, however as we would only invoice on the catch weight it isn’t possible to place your order online. Therefore if you have a requirement for our prestressing steel or would like further information please contact our Sales Office on 01772 369345 or email: sales@amfsteel.co.uk.

What is PC strand?

PC Strand, or prestressed concrete steel strand, is a twisted steel cable composed of 2, 3, 7 or 19 high strength steel wires and is stress-relieved (stabilized) for prestressed concrete or similar purposes. It can be classified according to the surface morphology and can be divided into: smooth steel strand, scoring strand, mold pulling strand (compact), coated epoxy resin steel strand. They can also be classified by diameter, or intensity level, or standard.

Manufacturing

Using high-carbon steel wire rod, after surface treatment it is cold drawn into steel wire, and then the strand structure will be a number of steel wires stranded into shares. Next the elimination of stress by way of a stabilization process. In order to extend durability, the wire can have metal or non-metallic coatings, such as galvanized, or epoxy resin coating. In order to increase the bond strength with the concrete, the surface can have nicks and so on. The prestressed strands of the mould are twisted to form a mould compression process, the structure is more compact, and the surface layer is more suitable for anchoring. Production of unbonded prestressed steel strand (unbonded steel strand) using ordinary prestressed steel wire, coated with oil or paraffin after the packaging into high-density polyethylene (HDPE) bags.

Features

The main characteristic of the prestressed steel strand is high strength and relaxation performance is good, the other when the more straight. Common tensile strength levels of 1860 MPa, as well as 1720, 1770, 1960, 2000, 2100 MPa and the like intensity levels. The yield strength of this steel is also higher.

Advantages of Prestressed Slabs

- Larger slab spans allowing fewer columns.

- Savings in materials (concrete and steel) also shorter lead times due to fast installation.

- Significant reduction in building weight versus a conventional concrete building.

- Reducing the occurrence of cracks.

- Allowing extremely long span bridges to be constructed without the use of temporary intermediate supports, and this minimizes the impact on the environment and avoids disruption to water or road traffic below.

Application

In most of the post-tensioned and pre-tensioned prestressed project, smooth steel strand is the most widely used prestressed steel. Stranded strand is mainly used to enhance the project, but also for nuclear power and the like works. Galvanized steel strand commonly used in the bridge of the tie rod, cable and external prestressing works. Epoxy coated steel stranded wire is similar to galvanized prestressed steel wire.

Standards

Countries have standards for prestressed strand, such as: China Standard GB / T 5224, American Standard ASTM A416, British standard BS 5896 and the Japanese standard JIS G3536